- Home

- Products

- About Us

- Company

- Service

- Solution

- Contact Us

Quantity

-

+

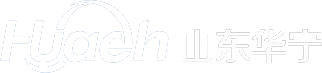

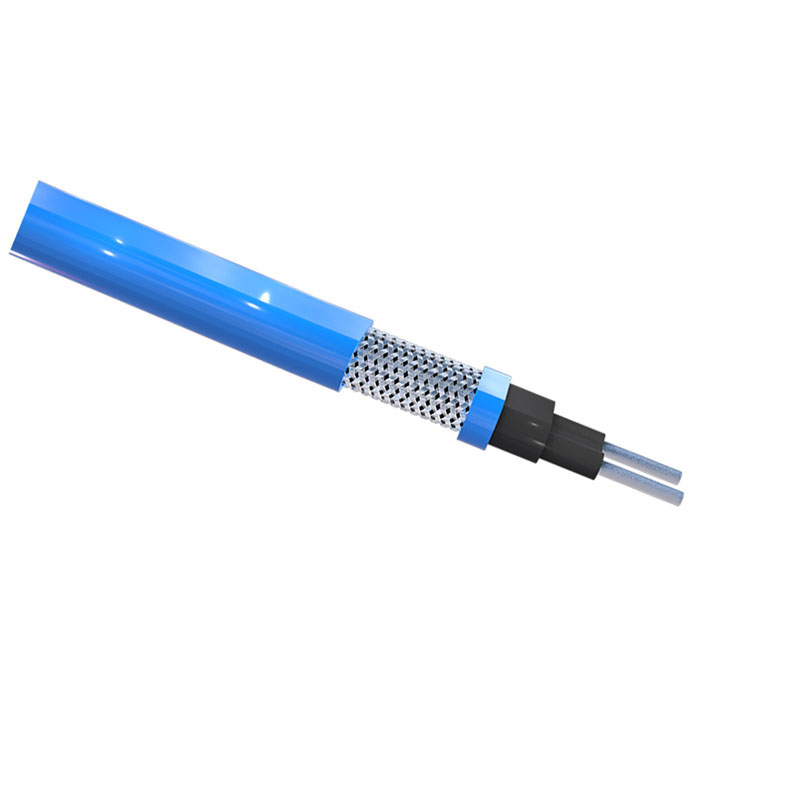

QYYEQ Type Oil Submersible Power Cable

Purpose

This product is suitable for supporting power supply for oil submersible pump units with rated voltage less than 3KV or less than 6KV.

Usage Characteristics

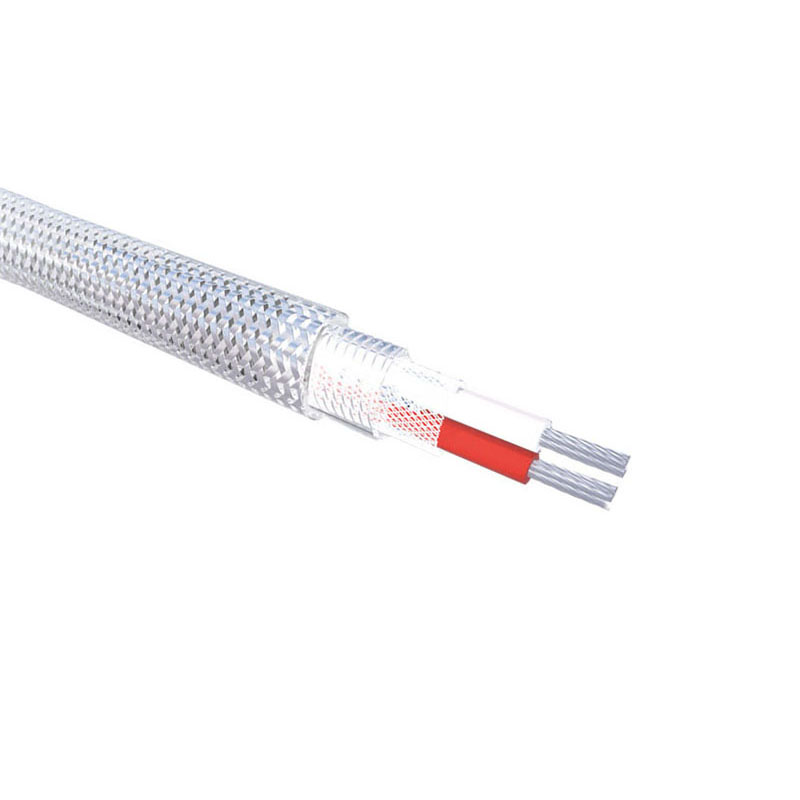

Conductor long-term working temperature is 150-232°C, with good oil resistance, heat resistance, and corrosion resistance.

Model

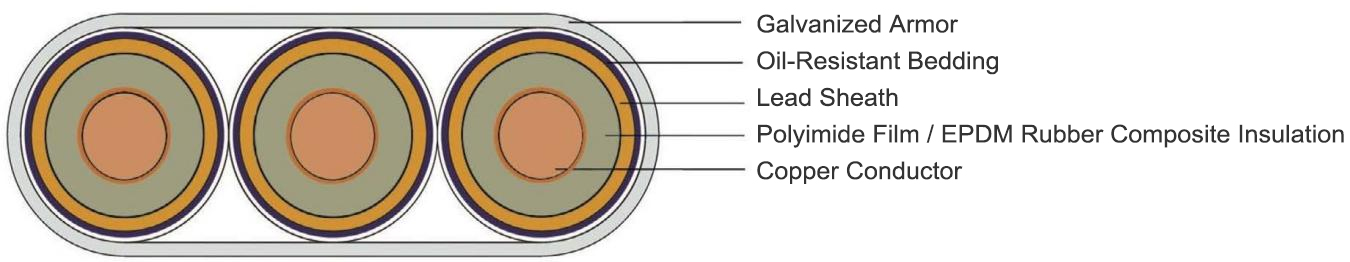

Polyimide - F46 composite film sintering / Tri-component ethylene propylene diene monomer rubber composite insulation, lead sheath, polytetrafluoroethylene tape / fiber tape wrapping, galvanized (stainless steel, Monel) steel tape armored flat submersible pump power cable.

Production Range

Voltage: 3KV, 4KV, 5KV, 6KV

Temperature: 150-232°C

Execution Standard: GB/T16750-2015, API RP 11S6

Structure Diagram

Technical Performance:

| Quantity of Core | Nominal Cross Section AWG /mm2 | Number of Conductors / Diameter mm | Conductor DC resistance 20℃ ≤ Ω/Km | Insulation Nominal Value Thickness mm | Sheath Nominal Value Thickness mm | Cable Dimensions and Weight (flat cable) | |||||

| 3KV | 6KV | ||||||||||

| NO Tinplating | 3KV | 6KV | 3KV | 6KV | mm×mm | Kg/Km | mm×mm | Kg/Km | |||

| 3 | 5/16 | 1/4.62 | 1.15 | 1.9 | 2.3 | 1.0 | 1.0 | 13×36 | 2230 | 14×37.5 | 2430 |

| 3 | 4/20 | 1/5.19 | 0.84 | 1.9 | 2.3 | 1.0 | 1.0 | 14×38 | 2464 | 14.5×39 | 2752 |

| 3 | 2/33 | 1/6.54 | 0.55 | 1.9 | 2.3 | 1.0 | 1.0 | 15×43 | 3143 | 16×43 | 3348 |

| 3 | 1/42 | 1/7.35 | 0.44 | 1.9 | 2.3 | 1.0 | 1.0 | 16×45 | 3575 | 17×47 | 3880 |

| Nominal Cross-sectional Area mm2/AWG | Nominal Diameter of the Conductor | 1.9 mm Insulation Resistance MΩ·Km | 1.9 mm Leakage Current μA/ (Kv·Km) | 2.3 mm insulation resistance MΩ·Km | 2.3 mm Leakage Current μA/ (Kv·Km) | DC withstand voltage - 5 minutes | |

| 3KV | 6KV | ||||||

| 16/5 | 4.62 | 3800 | 0.51 | 4082 | 0.48 | 27 | 35 |

| 20/4 | 5.19 | 3380 | 0.58 | 3738 | 0.50 | 27 | 35 |

| 33/2 | 6.54 | 2650 | 0.63 | 3121 | 0.54 | 27 | 35 |

| 42/1 | 7.35 | 2405 | 0.70 | 2841 | 0.61 | 27 | 35 |

Delivery Requirement:

Delivery can be made within a minimum of 1,000 meters, and it will be packed in full steel corrugated boxes.

Storage and Transportation Instructions:

For the rolled-delivered cables, the outermost layer of the cable should be 100 mm away from the edge of the corrugated all-steel cable reel. The cables must not be knocked against or twisted. Both ends of the cable should be protected against moisture.

English

English Español

Español Français

Français Русский

Русский العربية

العربية

Welcome to send your message to us