- Home

- Products

- About Us

- Company

- Service

- Solution

- Contact Us

-

QYYEQ Type Oil Submersible Power Cable

Purpose

This product is suitable for supporting power supply for oil submersible pump units with rated voltage less than 3KV or less than 6KV.

Usage Characteristics

Conductor long-term working temperature is 150-232°C, with good oil resistance, heat resistance, and corrosion resistance.

Details -

QYYFF Type Oil Submersible Power Cable

Purpose

This product is suitable for supporting power supply for oil submersible pump units with rated voltage less than 3KV or less than 6KV.

Usage Characteristics

Conductor long-term working temperature is 232°C, with good oil resistance, heat resistance, and corrosion resistance.

Details

ESP Cable

The Huaning ESP cable portfolio is designed to meet and exceed global industry standards, offering a range of configurations for various operating voltages and temperature ratings. Our focus on robust construction and meticulous quality control at every production stage translates into a product that minimizes electrical failures, reduces costly workovers, and extends the mean time between failures (MTBF). This directly contributes to lower total cost of ownership for our clients and supports more sustainable and predictable production operations.

At Shandong Huaning, we are not merely manufacturers; we are partners in productivity. Our venture into ESP cable technology signifies our dedication to driving the future of downhole equipment by applying our proven technological prowess to new challenges. We are committed to providing tailored, reliable solutions that empower the global energy industry to operate more efficiently and safely. Welcome to a new era of dependable downhole power, engineered by Huaning.

At the forefront of the pursuit for energy efficiency and operational reliability, Shandong Huaning proudly introduces its new generation of Electric Submersible Pump (ESP) cables, engineered to redefine the standards of downhole power transmission.

Forged from our deep expertise in thermal and electrical solutions for extreme environments, these cables are built to withstand the most demanding downhole conditions—extreme pressures, high temperatures, and corrosive media. We utilize advanced materials and precision manufacturing to ensure exceptional dielectric strength, superior chemical resistance, and long-term mechanical durability. This focus on robust construction minimizes power losses and prevents premature failures, directly enhancing pump efficiency and maximizing mean time between interventions.

Our commitment extends beyond the product itself. We provide tailored cable configurations and technical support, partnering with operators to optimize overall system performance and total cost of ownership. By setting a new benchmark in reliability and efficiency, Shandong Huaning’s ESP cables power not just pumps, but also the sustainable future of energy extraction, ensuring stable and productive operations worldwide. This is downhole power transmission, redefined.

1. Engineered for Extreme Reliability: Built to withstand the harshest downhole environments—extreme pressure, high temperature, and corrosive fluids—ensuring maximum uptime and minimizing costly workovers.

2. Optimized for Peak Efficiency: Utilizing advanced materials and precise design to reduce power losses and enhance electrical stability, directly contributing to superior system performance and lower energy consumption.

3. Proven Durability & Longevity: Manufactured with premium, corrosion-resistant materials and rigorous quality control to deliver extended service life and a lower total cost of ownership over the cable's lifecycle.

4. Partnership-Driven Technical Support: Moving beyond supply to provide tailored solutions and expert collaboration, ensuring seamless integration and optimal performance for your specific operational challenges.

Engineered for Extreme Reliability

Our ESP cables are specifically designed to deliver unwavering performance in the most severe downhole conditions. They are engineered to resist the triad of extreme downhole challenges: intense pressure, elevated temperatures, and highly corrosive fluids (such as H₂S and CO₂). Through the use of premium, chemically inert materials and robust construction, we prevent insulation degradation, electrical failure, and mechanical damage. This dedicated focus on durability ensures maximum operational uptime by significantly reducing the risk of costly, unexpected cable-related shutdowns, providing a foundation of dependable power transmission for continuous production.

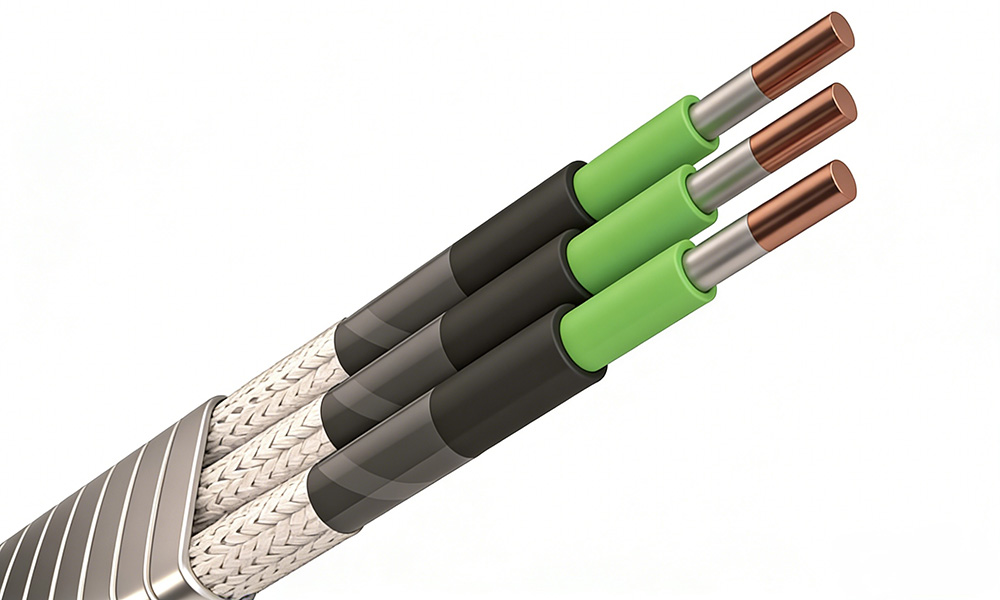

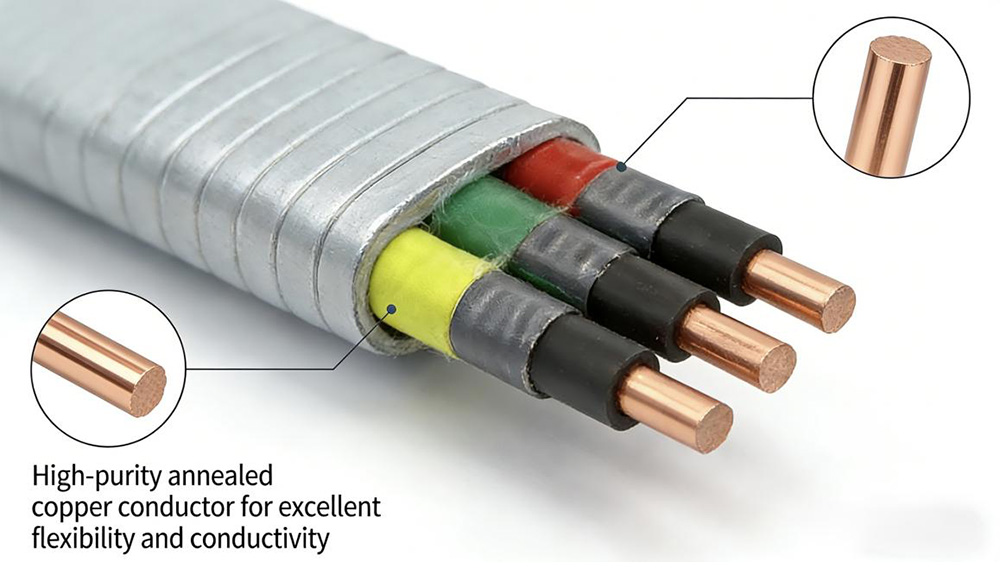

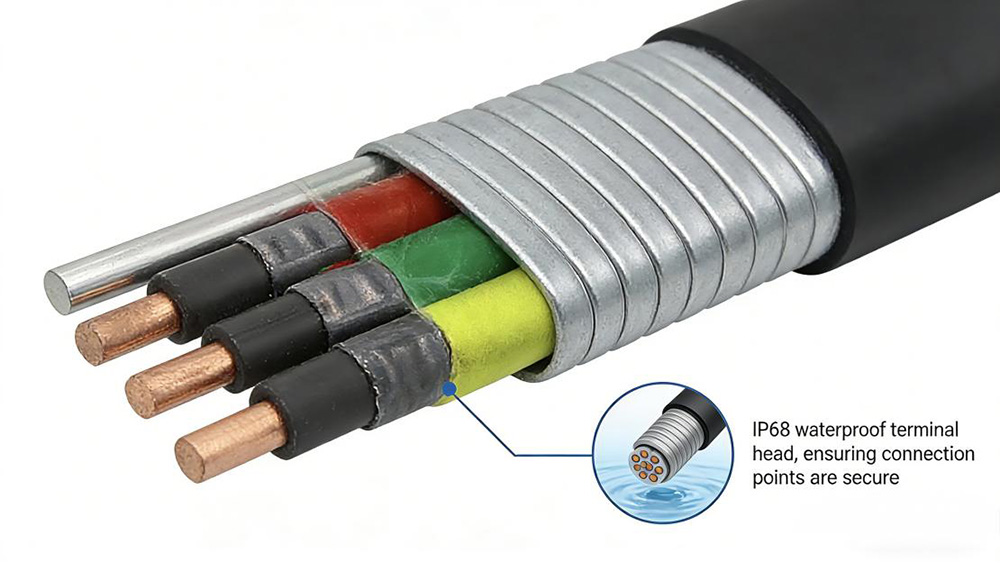

1. High-purity annealed copper conductor with excellent flexibility and conductivity.

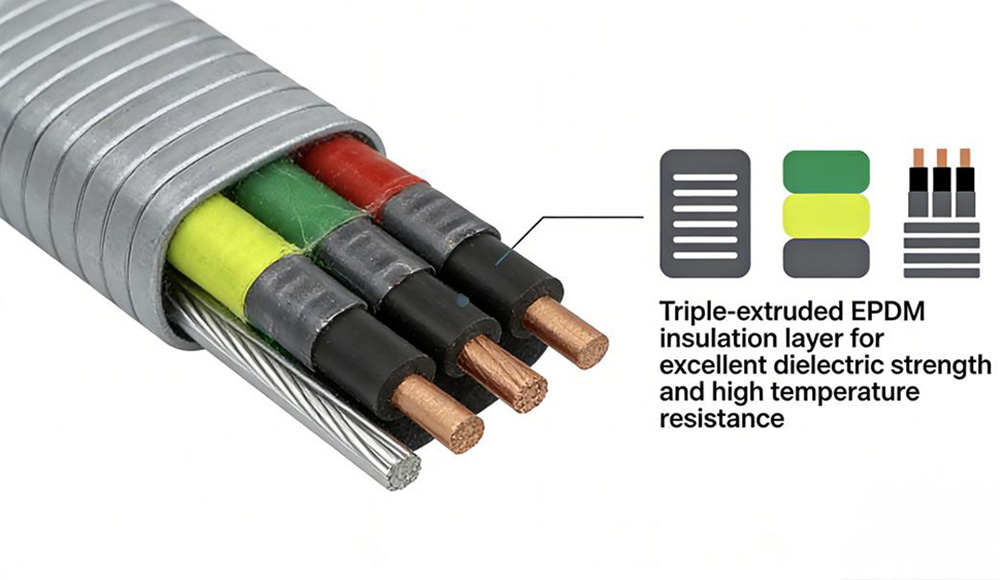

2. Triple-extruded EPDM insulation layer for excellent dielectric strength and high temperature resistance.

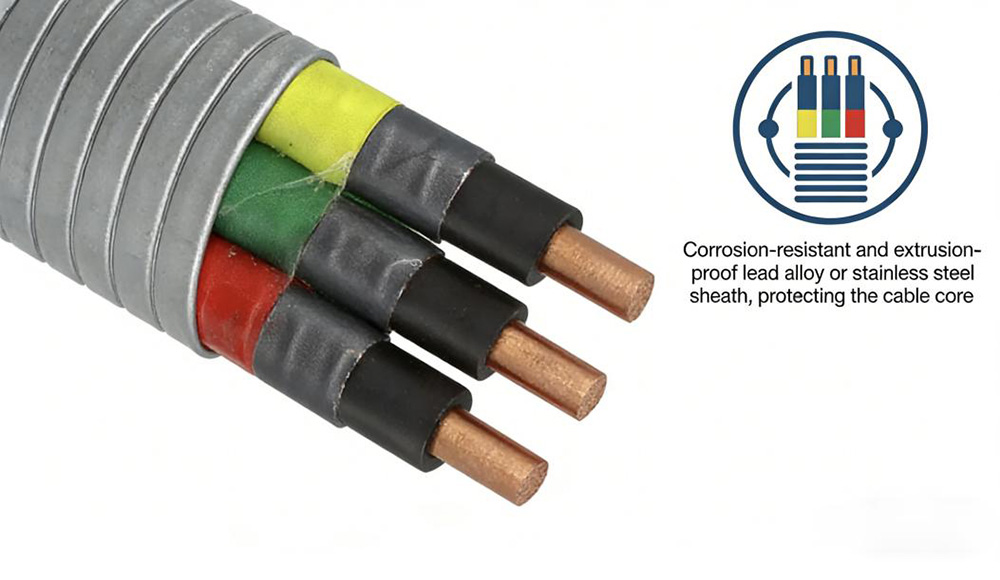

3. Corrosion-resistant and extrusion-proof lead alloy or stainless steel sheath, protecting the cable core.

4. IP68 waterproof terminal head, ensuring connection points are secure.

5. Special composite material sheath, resistant to H₂S、CO₂, and down-hole chemicals.

English

English Español

Español Français

Français Русский

Русский العربية

العربية

Welcome to send your message to us